The United Auto Workers are striking all three of America’s major automakers — General Motors, Ford, and Stellantis — simultaneously for the first time in history. The UAW boasts the sympathies of three-quarters of the U.S. public and can mobilize tens of thousands of voters in pivotal Electoral College battlegrounds.

This represents both a challenge and opportunity for the Republican Party. On the one hand, the UAW’s discontent could sap its support for the incumbent president. On the other hand, the conservative movement exists to help corporate managers quash challenges from below.

Some prominent Republicans have proven unable to suppress their contempt for organized labor long enough to stoke autoworkers’ skepticism of Biden. Asked about his views on the UAW strike, South Carolina senator (and doomed presidential candidate) Tim Scott replied, “I think Ronald Reagan gave us a great example when federal employees decided they were going to strike … He said, ‘You strike, you’re fired.’ Simple concept to me. To the extent that we can use that once again, absolutely.”

Of course, the president does not have the authority to fire striking private-sector workers. So unless Scott is calling on Biden to nationalize the Big Three, his remarks are a bit of non sequitur, conveying nothing save his solidarity with miserly corporate executives.

But other Republicans have navigated the issue with a bit more finesse. A wide array of GOP lawmakers have expressed sympathy for the UAW workers, but framed the strike as a conflict between blue-collar laborers and a president beholden to environmentalists (and/or the Chinese Communist Party). The idea here is that the fundamental threat to autoworkers’ livelihoods is the transition to electric vehicles, a shift that Joe Biden’s policies have engineered.

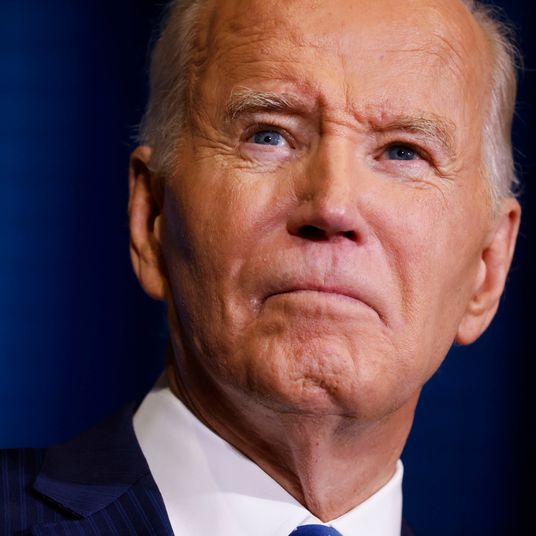

As Donald Trump recently put the point, Biden “will murder the U.S. auto industry and kill countless union autoworker jobs forever, especially in Michigan and the Midwest. There is no such thing as a ‘fair transition’ to the destruction of these workers’ livelihoods and the obliteration of this cherished American industry.”

This line of attack is essentially dishonest. U.S. automakers are not transitioning to EVs because of the Inflation Reduction Act. Rather, they are doing so in response to both investor and consumer demand. The IRA may accelerate the transition’s pace. But it also gives U.S. workers a better chance of prospering in an EV-centric auto sector by subsidizing domestic production of both electric vehicles and their inputs. Meanwhile, Biden’s labor policies are far more conducive to the UAW’s aims than the Trump administration’s were.

Nevertheless, Trump’s talking points could resonate, as they speak to the UAW’s real — and well-founded — anxieties about the EV transition’s implications for autoworkers in general, and unionized ones in particular. There is no reason in principle why the U.S. auto industry cannot simultaneously raise its labor standards and become globally competitive in EV production. But at present, the green transition looks poised to transfer jobs away from unionized auto plants to nonunion EV and battery production facilities.

Achieving a just transition for autoworkers will likely require federal policy to become more conducive to labor organizing, the Big Three automakers to increase their productivity and technological acumen, and the UAW to organize EV and battery factories in some of the most anti-union regions of the country. Bringing all that about will not be easy. And a second Trump administration would surely make a fair transition all the harder.

Why UAW workers are worried about the green transition

The UAW strike is about a lot more than EVs. After the 2008 crash, as America’s automakers trembled on the precipice of collapse, their unionized workers made concessions in order to keep their employers alive. The expectation was that these reductions in labor standards would be temporary. The reality is that they have persisted, even as the Big Three returned to record profitability (and allowed their top executives to reap the fruits of these boom times via gargantuan salaries).

The UAW therefore aims to secure a 36 percent wage increase, a contractual cost-of-living adjustment to protect that wage gain from inflation, an end to the practice of older workers enjoying more generous compensation terms than younger ones, and defined benefit pensions, among other things.

Nevertheless, the UAW’s militancy is informed by the knowledge that this is a pivotal moment in the history of its industry. The Big Three will need to dramatically reorganize production to compete in a world where EVs predominate. And the firms look poised to execute this transition in a manner that contravenes the interests of unionized autoworkers.

For the UAW, some of the EV transition’s risks have little to do with the technology itself. For decades, U.S. automakers have been shifting production toward southern “right to work” states that are both legally and culturally resistant to labor organizing. The Great Lakes region remains the heart of U.S. auto production. But since the 1990s, new factories have been concentrated overwhelmingly in the South. Since EV and battery production has distinct requirements from conventional auto-building, firms need to build many new facilities to roll out their EV lines. Following preexisting industry practice, the Big Three have tended to locate these facilities in nonunion areas. As a result, only about a quarter of EV factories in the U.S. employ unionized workers, according to the BlueGreen Alliance Foundation, a pro-labor environmental group.

Yet the distinct labor and production demands of electric vehicles exacerbate the UAW’s predicament. EVs are much simpler machines than internal-combustion engine cars. The latter’s gas engines and transmissions require hundreds of intricate components. EVs, by contrast, require no carburetors, pistons, or spark plugs. An electric vehicle’s powertrain is just an electric motor and battery pack.

As a result, it takes less labor to assemble an EV than an ICE vehicle. Ford and Volkswagen have estimated that EV production will require 30 percent fewer work hours than the ICE variety. Meanwhile, autoworkers who’ve attained special skills in the production of gas-engine inputs will see a steady decline in demand for their aptitudes.

Still, it is not inevitable that the EV transition will disemploy a large share of the auto sector’s existing workforce. Although it takes fewer workers to assemble an electric vehicle once one has all the parts, it’s not actually clear that less labor will be required to build EVs when one accounts for battery production. A recent study from researchers at Carnegie Mellon University found that EVs actually require more overall work hours than ICE cars due to the labor demands of manufacturing battery cells.

At the moment, we can’t be certain about precisely what the labor demands of a mature American EV industry will look like. But one thing seems clear: If UAW workers cannot secure positions in battery production, then the transition will reduce both their employment and the union density of America’s auto sector.

“Batteries are the power trains of the future,” Dave Green, the UAW’s regional director for Ohio and Indiana, told the Associated Press. “Our workers in engine and transmission areas need to be able to move into the new generation.”

For this reason, one of the UAW’s strike demands is for the Big Three to sign agreements granting the union representation of the workers at their battery plants. The automakers insist that they do not have the legal authority to make such a concession, since they have generally partnered with foreign firms to build their battery plants, as U.S. companies have less experience with the technology. Since these factories are joint ventures, Ford, GM, and Stellantis say that they cannot unilaterally ink agreements over labor representation at such facilities.

Of course, the carmakers would not want to make such a concession even if they could. American EV battery producers are at a competitive disadvantage in the global market due to their late entrance into the sector. China’s early investments in EVs have enabled it to amass 75 percent of global battery production capacity. With privileged access to this mature and massive battery industry, Chinese EV producers have secured a dominant position on the world market, selling two-thirds of all EVs over the past year. And, of course, Chinese battery and electric-vehicle producers have much lower labor costs than their American counterparts.

Historically, U.S. firms have been able to compete with low-wage foreign competitors on the strength of their technological superiority. But U.S. battery-makers find themselves in the novel position of trying to compete with foreign rivals that have both a technological head start and much cheaper labor at their disposal.

For now, high tariffs are keeping Chinese EVs off the U.S. market. But duties on Chinese batteries are lower. And American tariffs cannot stop Chinese EV makers from eating into U.S. carmakers’ sales in Europe and Asia.

Further, Chinese firms are scarcely the Big Three’s only low-wage competition. According to Ford, the Big Three’s average hourly labor cost (including the monetary value of benefits) is $65, while that of nonunion automakers located in the U.S. is $55. The companies’ main domestic competitor in the EV market, Tesla, has even lower labor costs of between $45 and $50 per worker hour.

At the same time, launching new EV businesses requires large up-front capital costs. As a result, the Big Three are currently losing billions of dollars on their EV operations. Combine competitive pressures with these large capital expenses, and you get automakers highly resistant to the UAW’s demands and aspirations. For the UAW, it is imperative to dramatically increase labor standards and unionization rates within the EV sector. In the view of the Big Three’s managers, preventing that development is a precondition for remaining competitive with electric-vehicle pioneers, both foreign and domestic.

Therefore, to prevent the EV transition from hurting its membership, the UAW likely needs to find a way to organize EV and battery plants throughout the South — where the union has struggled to make gains in recent years — in defiance of managers who see containing labor costs as an existential imperative. It is entirely reasonable for autoworkers to be worried about their union’s prospects for pulling this off.

The Inflation Reduction Act is part of the solution, not part of the problem

The Big Three’s concern that high labor costs will render them uncompetitive isn’t irrational. But it is overstated. The truth is that labor accounts for a tiny fraction of the cost of EV production, which is highly capital-intensive. The primary reason why the Big Three have fallen behind Tesla and Chinese EV-makers is not that they pay generous wages; adjusted for inflation, wages for autoworkers in the U.S. have fallen by 19 percent since 2008. Rather, the Big Three’s fundamental problem is that they failed to anticipate the speed at which investors and consumers would turn toward EVs. Chinese firms, and start-ups like Tesla, got a big head start on making EVs and used it to develop superior technology, production techniques, and supply chains.

Given this reality, it’s clear Biden’s subsidization of American EV production is not the cause of the UAW’s plight, so much as one small part of the potential solution to it. The problem isn’t that the U.S. government is encouraging the Big Three to get into the EV business, but that it is doing so a decade too late.

Federal policy can accelerate the transition toward electric vehicles. But it is not the principal driver of that global economic trend. Whether the Republican Party cares to admit it, climate change is a genuine crisis. Governments the world over are invested in reducing carbon emissions and see the replacement of ICE cars with EVs as one of the more politically palatable means of doing so. Thus, even if the U.S. refrained from subsidizing EV purchases, the European Union, China, and other developed nations would.

At the same time, purely from the consumer’s standpoint, EVs have clear advantages over ICE vehicles. They are quieter and cleaner; they accelerate faster and are far cheaper to maintain. As governments build charging stations and battery technology improves, the superiority of EVs is liable to become overwhelming. For this reason, capital markets favor producers of EVs over conventional carmakers. As of this writing, Wall Street values Tesla at $244 a share while pricing Ford at a mere $12.50. Such “free market” forces, combined with foreign government’s policies, are driving the EV transition far more than anything the U.S. government has done.

If the Inflation Reduction Act has not authored the EV transition, it is guiding that shift in a direction more favorable for U.S. autoworkers. In order to access the law’s tax credits for EV purchases, at least 50 percent of the components in a vehicle’s battery must be assembled or manufactured in North America. That percentage increases over time until it reaches 100 percent by 2029. In the absence of this incentive for North American battery production, it’s likely that an even larger share of that sector’s jobs would be concentrated in China.

More broadly, by publicly subsidizing U.S. EV production, the IRA makes it a bit easier for the Big Three to make the investments necessary for becoming more technologically competitive. There is no reason in principle why U.S. automakers cannot out-innovate their rivals and achieve productivity gains that enable them to pay superior wages while delivering a superlative product. Had Washington done as much as Beijing to nurture our nascent EV industry over the past decade, the Big Three would likely be in a better position today. Now, they have no choice but to play from behind. But federal support should make them more likely to catch up to the competition.

This said, the UAW has some legitimate grievances with the White House. In its efforts to abet U.S. EV production, the Biden administration provided Ford with a $9.2 billion loan to build joint-venture battery plants in Kentucky and Tennessee without requiring the company to pay union-standard wages. Those plants are now hiring workers for jobs that pay between $21 and $29 an hour. Workers building engines and transmissions at Ford’s unionized plants, by contrast, earn between $28 and $35 an hour. Thus, from the UAW’s vantage, the administration appears to be subsidizing the replacement of good jobs with bad ones.

Precisely how much legal authority the administration has to append pro-labor conditions to its loan programs is contested. But it is fair to say that both the IRA and its implementation process have not done enough to prevent the EV transition from accelerating the secular trend toward worse labor standards in the U.S. auto sector. The federal government can do more to abet union organizing in the “right to work” South and incentivize corporate recipients of federal subsidies to treat their workers well.

But Biden’s Republican critics have no intention of doing either of those things. Trump has no interest in taking autoworkers’ side in their conflicts with management, only in exploiting their anxieties about electric vehicles for political gain.