Welcome to Jeans Month on the Strategist, where we’re obsessively vetting denim — from trying on every pair at the Gap to asking dozens of stylish people about their favorite fits. For more, head to our Jeans Month hub.

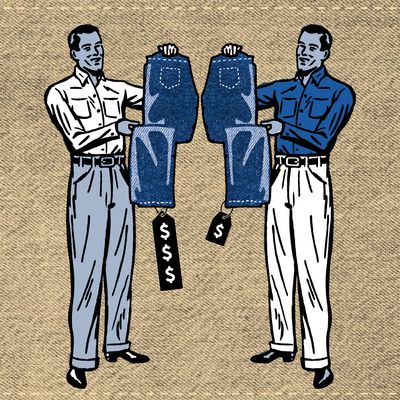

Levi Strauss patented the “blueprint for the blue jean” — the design that would become the 501 — back in 1873, and at the turn of the century, a pair of Levi’s could cost you about $1.25. More than 100 years later, 501s now start at $78.50. That places them on the lower end of the jeans-price scale, where you’ll find Target’s Universal Thread Sailor going for lower still at $28; Madewell’s Low-Slung Baggy somewhere in the middle at $148; and, on the higher end, Agolde’s Low Curve and Mother’s Rambler for $238 and $288, respectively. Truthfully, there’s no “right” price for a pair of jeans. But you might be wondering what actually differentiates jeans at these wildly different prices.

How much a pair of jeans costs can depend on the usual suspects — markups, marketing, changing profit margins, and that catchall term: inflation — but, ultimately, the price tag comes down to the production process. Factors like the location of a production factory, the kind of cotton and dye used, and even the stitches per inch on a seam can impact the price. The labor involved in making the jeans adds to the cost too. “The cash register keeps ringing as somebody else is handling your jeans,” says Deborah Young, an assistant professor who teaches about textiles at ASU FIDM. According to gently.nyc’s Alyss Odle, a pair of $30 jeans will typically be mass produced, while the $300 jeans won’t be. That’s not to say that the $300 jeans are better, or that the $30 jeans are worse, per se. “It’s like the difference between a ballpoint pen and a fountain pen,” says X’s “Menswear Guy,” Derek Guy.

It all starts on a loom.

Generally, there are two ways to make denim: on a projectile loom or a shuttle loom. On either machine, cotton gets woven into a twill fabric (that’s all denim is). The difference between the looms — and the jeans they produce — lies in efficiency. A projectile loom shoots out denim, while a shuttle loom, which was traditionally used to make jeans pre-WWII, shuffles it out. “Most denim is produced on a projectile loom now,” says Amy Leverton of consultancy firm Denim Dudes (clients include Levi’s and Lee). Projectile looms offer mass production and the low prices that follow, putting out millions of yards of denim a year, says Odle. “But the speed and volume that you can produce with a projectile leaves a lot of room for quality-control errors,” she adds.

While shuttle looms fell out of fashion around the middle of the last century, they’re still used today to make jeans that typically come at a higher price point. Jeans with a selvedge, or self-edge, stripe are an example of this — the finishing technique makes seams less likely to come undone (versus projectile loomed jeans, where the edge is finished separately and is more likely to fray). Shuttle-manufactured denim might be “a little bit heavier, a little bit rougher, and a little bit more uneven” than the projectile-manufactured kind, Guy says — which is part of what you’re paying for. “Denim-heads prefer shuttle looms because the slower process allows for more character,” Leverton tells me. A big selling point of Japanese denim — where prices tend to be well into the hundreds — is that it’s often done on a shuttle.

Pay attention to a mill’s location.

Where the denim is made impacts price — to some extent. Denim made in Fukuyama’s famed Kaihara Mill — which supplies Nudie with its Rufus and Buck Mason with its Ford — tends to cost more. And Left Field uses Vidalia Mills in Louisiana; its Greaser and Chelsea styles sell for $230. But just because denim is loomed in the U.S. or Japan isn’t always an indicator of the quality of the denim. Leverton, who tells me she has toured a lot of factories around the world (including in Bangladesh, Pakistan, and China), believes that “it’s not where you make, it’s how you make, because I have seen good and bad everywhere.” As a rule of thumb, be wary of any jeans that don’t tell you anything (even in the fine print of an “About Us” page). “Any brand that’s actively talking about their ingredients (where the cotton comes from, etc.) is proud and you can probably trust them,” adds Leverton.

So what makes $300 jeans cost so much?

It’s really the combination of production process and materials that makes jeans pricey. Usually, more expensive jeans will be made completely out of cotton. (For what it’s worth, in all my years as the Strategist’s denim correspondent, I can’t remember ever seeing a pair of jeans over $300 that wasn’t printed with “100 percent cotton” on the care tag.) “When you let the cotton be in its most pure form throughout the process, you’ll get that better quality out of it,” says Odle. “I could use the best cotton on earth and if I just put a bunch of crap in it, it’s not going to be as good.” Polyester is a filler commonly seen in less expensive jeans, which often leads to the fabric feeling thinner. Without the use of synthetics, you’re generally getting jeans that are weightier (you’ll see a higher denim weight listed in ounces commonly) and that’ll be hard-wearing and last longer.

A higher price point comes with a more involved level of craftsmanship and detail, too. “They’ll definitely have certain stitching and hardware elements that lean toward durability: metals like brass and copper for buttons and rivets, as well as details like extra bar-tack stitches and chain-stitched hems added to make sure the piece lasts long,” Odle explains, noting that these usually aren’t found in less expensive pairs. You might also notice more detailed product-description pages online, which include precise size measurements down to the inseam. But you don’t necessarily need to pay $300 for these things. For around $150 — a typical price for jeans from Madewell, Reformation, and Everlane — you’ll start to see jeans that are 100 percent cotton (or at least 99 percent cotton and one percent elastane) and that come in more varied washes than just “light” and “dark.” Pairs in this price range also tend to have better tailoring — leading to a better fit — than those at a lower price point.

And what makes $30 that much less expensive?

When you buy a pair of jeans for $30, you’re going to be getting jeans made of a thinner denim that usually includes synthetics (polyester, elastane, Lycra) and may very well not survive a spin cycle despite being “machine washable.” Jeans at this price point tend to be made under a fast-fashion model, says Odle. Because of the “insane mass scale” in the making of these jeans, “you’re going to get inconsistencies in the fabric, which is why you’ll hear someone say, This pair doesn’t fit like the last one. That’s from being woven thinner, because you can obviously get more bang for your buck that way. But that leads to breaks, tears, and jeans becoming more misshapen over time,” she adds. Many jeans at this price point are designed to be disposable. A repair for a hole might cost more than the jeans themselves, Guy points out. (Some premium-denim companies will offer repairs free of charge or for a small additional fee.)

That said, you’re getting a bargain. And unlike $300 jeans, $30 jeans are probably going to be comfortable from the moment you put your foot through the leg. The problem is “if they’re already ‘broken in,’ which is an easy sell a lot of the time, you’ve lost half the life of the jeans,” Odle says. Still, your $30 jeans might last you years, depending on how often you wear and wash them. Back to Guy’s ballpoint pen and fountain pen analogy: “There’s a reason why most people use ballpoint pens: Because they’re incredibly convenient. But a ballpoint pen will never have the character of a fountain pen.” And as was oft repeated to me in interviews, it’s not always about quality. It’s about what you want out of your jeans. And maybe that doesn’t have to cost you $300.

Some of our most stood-behind jeans (at every price point)

The Strategist is designed to surface useful, expert recommendations for things to buy across the vast e-commerce landscape. Every product is independently selected by our team of editors, whom you can read about here. We update links when possible, but note that deals can expire and all prices are subject to change.